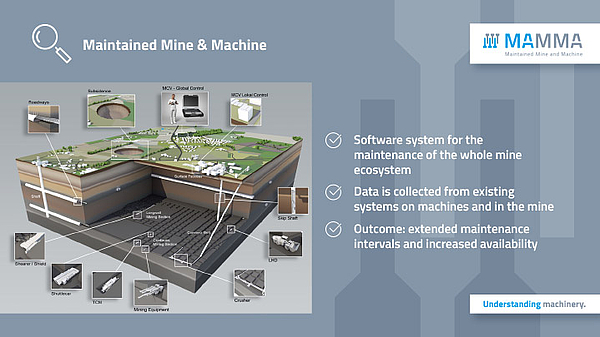

Customizing an application-system for monitoring, maintenance and assessment of the underground mining ecosystem

Project objective:

In this project the availability, efficiency and the safety of the machines and mine plant are improved using a smart, integrated and holistic maintenance system.

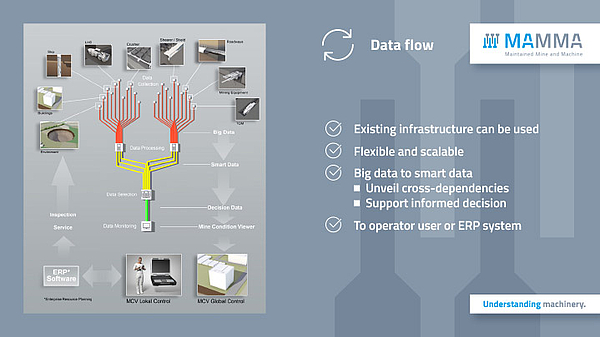

New existing IOT methods couple already installed control systems and measuring systems to a common data base. Thus new components can be connected to the System step by step or older ones uncoupled similarly. Besides, the System follows the need of the mine. Applications of DMT and MUL access the data base and make the outcome available to different experts.

Find out more about the ability of understanding machinery

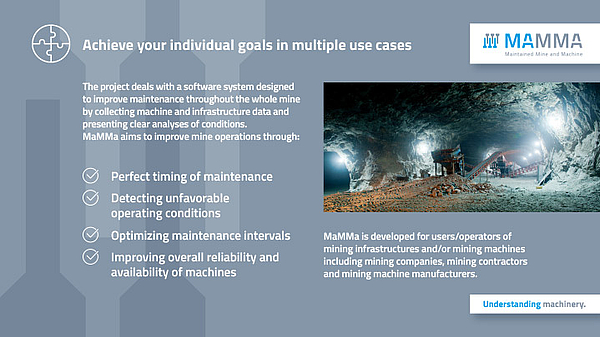

Do you want to reduce cost in your mining business easiliy by using MAMMA triple based maintenance system? Save up to 7,5 %

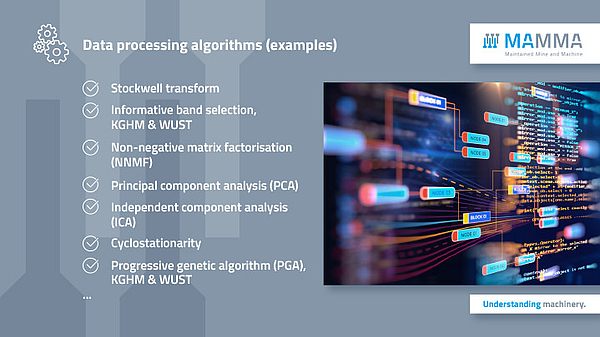

The proposed product will contain the steps from big data to smart data leading to the decision for inspection or service action.

This could be done for all machines and the mine workings, so that their dependencies will be pointed out and could be handled to improve the production.

To achieve these goals, MaMMa will use:

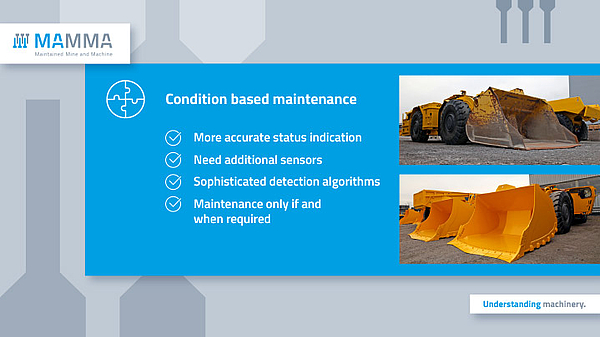

- CBM methods

- Wear and load profiling methods

- Decision support methods

- Interface to ERP system, e.g. SAP

This machine related information combined with the condition of the roadways and other geotechnical indicators leads to a more transparent mine operation and opens the way to process improvements.

The outcome of MaMMa will be a System handled by the customer to improve the value added chain. Different mine components will be included and TRL 8 level be achieved.

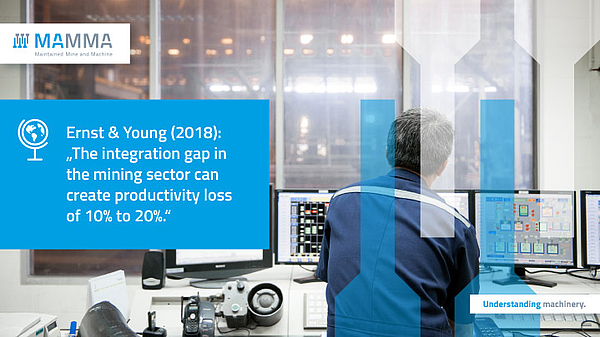

About MAMMA

The project deals with a software system to improve maintenance for the whole mine by collecting machine and infrastructure data and present analysed conditions in a clear way.

Therefore the data is collected from existing systems on machines and in the mine. This new product will lead to extended maintenance intervals and increased availability. Dependencies will be pointed out and could be handled to improve the production.

More about MAMMA:

Work packages

The following work packages support both the market launch and the evolution of the system into a surveillance system which creates a virtual view of the monitored mine by providing real-time and historical data on request.

By monitoring and analyzing this data a holistic approach to machinery, equipment and operations monitoring is sought.

Methods

The proposed product will contain the steps from big data to smart data leading to the decision for inspection or service action.

This machine related information combined with the condition of the roadways and other geotechnical indicators leads to a more transparent mine operation and opens the way to process improvements. The outcome of MaMMa will be a System handled by the customer to improve the value added chain. Different mine components will be included and TRL 8 level be achieved.

NEWS: Webinar - Introducing an application-system for monitoring, maintenance and assessment of the underground mining ecosystem, 26 November 2020

Do you want to reduce cost in your mining business easiliy by using MAMMAs Holistic monitoring approach? Learn how to save up to 7,5 % using combining event, load and condition monitoring.

This free webinar presents the Maintained Mine and Machine project (MAMMA). In MaMMa special algorithms have been developed which are made available on a specific internet platform. In this webinar we will present how the platform idea is implemented.

We show you:

- The advantages that a platform offers in daily work.

- The further future development steps of the MaMMa Cloud.

- Some special use cases. (LDH, conveyor and road monitoring)

- The cost advantages of the special algorithms in these use cases.

Further on will be shown examples how the platform is optimized with additional applications for your own needs and how the look of the platform can be adapted to your own design. After training, the user himself can carry these out.

Date & Time: 26 November 2020, 13:30 pm CET

Questionnaire

Your opinion counts. Please support our project through your participation at our questionnaire.

At this point you will find a questionnaire, which enables us to get to know you and your needs better and to offer you tailor-made concepts and solutions with the aim to present you sustainable optimization of your workflow and to implement them together with you.

So that you can achieve your goals in terms of productivity, efficiency and profit in the best possible way